10% of Nvidia’s Cost: Why the Tesla-Intel Chip Partnership Demands Attention

- byAman Prajapat

- 10 November, 2025

Listen up—there’s some big-time seismic rumbling in the tech world, and if you’re tracking AI hardware or the auto industry, you better lean in. Here’s the full story, laid out straight.

1. What’s happening?

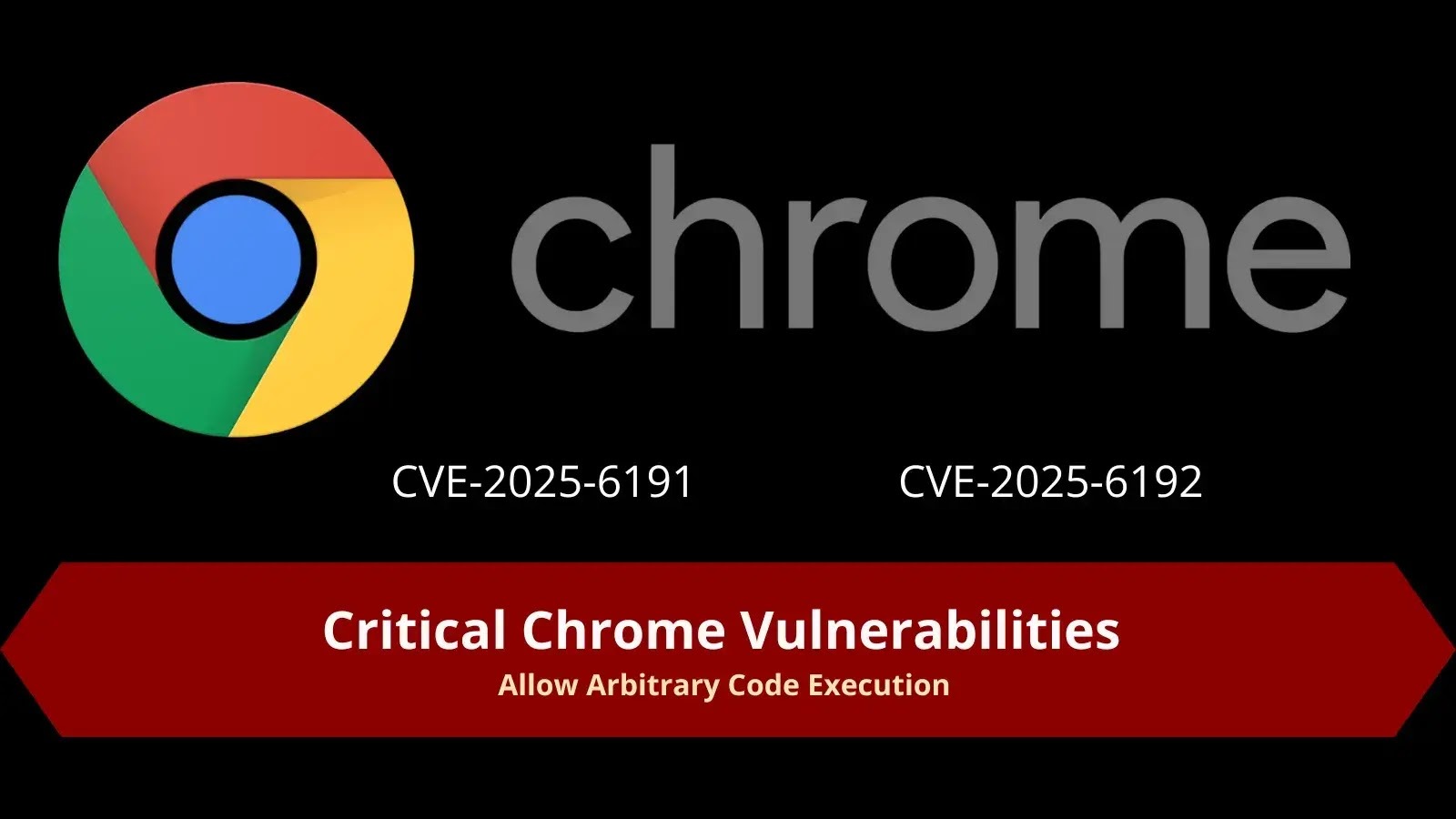

At its annual shareholder meeting, Tesla CEO Elon Musk dropped a bombshell (or at least a heavy hint): Tesla is designing its fifth-generation AI chip (dubbed “AI5”) to power its autonomous driving systems and robotics ambitions, and the company is seriously considering partnering with Intel to make it.

Here are the key bits:

Musk said the new chip would consume about one-third of the power used by Nvidia’s flagship “Blackwell” chip.

More astonishing: the manufacturing cost could be just 10% of what Nvidia’s chip costs to make.

Tesla is also considering building a massive new fabrication facility (a “terafab”) capable of at least 100,000 wafer starts per month—way bigger than a “giga” fab.

Tesla hasn’t signed a formal deal with Intel yet—but Musk said “maybe we’ll… do something with Intel” and that it’s worth discussions.

2. Why it matters (and you should care)

Alright, this isn’t just one more tech press release. The implications run deep. Here’s why I’m excited (and so should you).

Cost disruption: If Tesla can truly roll out AI-chips at 10% the manufacturing cost of Nvidia’s, the economics of deploying AI hardware change dramatically. Companies that build data centres, autonomous systems, robotics—they all want cheaper, more efficient chips.

Power efficiency: One-third the power means less energy use for the same tasks, or more tasks for the same power. That matters for scaling fleets of autonomous vehicles or robot platforms.

Supply chain & manufacturing shift: Tesla flirting with Intel signals a move away from relying solely on the usual suspects (like Taiwan’s TSMC or South Korea’s Samsung). Tesla sees a supply bottleneck and is trying to get ahead of it.

Intel’s revival narrative: Intel has been playing catch-up in the AI chip race; a deal with Tesla provides a major lifeline and opportunity.

Autonomous vehicles + AI hardware convergence: Tesla isn’t just an automaker anymore—it’s combining car manufacturing + AI + custom silicon + massive fab ambitions. That’s a multi-front war and could shift how we think about the “chip inside the car”.

Barriers to entry rising—or lowering? On one hand, building fabs is insanely expensive; on the other, if cost per chip drops, it may open up new players and new architectures.

3. The players in the ring

Tesla: Not just electric cars. They want autonomy, robots, AI hardware. They design chips in-house, now talking about in-house manufacturing / massive fab scale.

Intel: Has manufacturing infrastructure, foundry ambitions, and needs customers for its newest tech. Tesla could be that customer.

Nvidia: Currently dominates AI hardware (especially for data centres and training). The cost benchmark. Tesla’s claims revolve around costing a tenth of Nvidia’s manufacturing cost.

TSMC / Samsung: Existing manufacturing partners for Tesla and others, but Tesla sees constraints here. Tesla’s move suggests that relying purely on them might not be enough for scale.

4. Key questions & caveats

Hold up—before we all get starry-eyed, there are plenty of “ifs”.

Tesla claims cost “10% of Nvidia’s manufacturing cost.” But that’s a claim. Real-world yield, performance, defect rates, manufacturing logistics—all could change that number.

Performance vs cost: If Tesla’s chip uses one-third the power, that sounds great—but what about raw performance compared to Nvidia’s Blackwell chip? Is it equal, lower, or just optimized differently (e.g., for Tesla’s use-case)?

Timeframe: Limited production of AI5 is expected in 2026, with volume ramp in 2027. AI6 (next generation) could use the same fabs but double performance by mid-2028.

Building a fab: Tesla says they may need to build a “terafab”—that’s huge, hugely expensive, hugely complex. Supply chains, financial risks, logistics, regulatory approvals—it’s not trivial.

Intellectual property / ecosystem: Chips are only part of the story. Software, architecture, ecosystem support, tooling, supply chains—Tesla will have to excel at all.

Partnership terms: Tesla and Intel have no signed deal (as of the announcement), so this remains speculation.

5. Why shift from the “old way” matters

We often think of companies buying off-the-shelf chips and building systems around them. But Tesla is flipping the script: designing its own hardware, controlling its own fab potential, optimizing for its software stacks. That’s vertical integration at another level. And cost reduction (10%) is huge because every dollar saved per chip multiplies when you produce tens of millions of units (for vehicles, robotics, data centres).

Historically, large-scale chip manufacturing has required massive investment, long lead-times, and global supply chain complexity. If Tesla pulls this off, it means future auto/robotic/AI companies might aim for similar models—from chip design to manufacturing to system deployment—rather than just outsourcing.

6. What this might mean for various stakeholders

Auto industry & EVs: Tesla’s move raises the bar for what “autonomous vehicle hardware” looks like. Competitors may feel pressure to design their own silicon or partner differently.

AI/ML data‐centre operators: Reduced cost chips could reduce the barrier to building AI infrastructure, democratizing some parts of it (though performance trade-offs will matter).

Semiconductor industry: Foundry capacity becomes more strategic; national policy (e.g., domestic manufacturing in the U.S.) becomes more central.

Consumers: Over time, cheaper chips could reduce cost of self-driving features or robotics. But timelines are long.

Investors: Companies like Intel, Tesla, Nvidia will be closely watched. The stock reactions are already visible.

7. The big takeaway

In a nutshell: Tesla’s potential partnership with Intel and its chips-at-10%-of-cost claim is not just hype. It’s possibly a pivot point. If what they claim is realised (or even partially realised), we could see:

A cost collapse in AI chip manufacturing (for certain use-cases)

A structural shift in how cars, robots, and AI systems are built (more vertical integration)

New pressure on existing major chip players (like Nvidia) to defend their cost/performance advantage

A reshaping of global supply chains, manufacturing geographies, and strategic dependencies

If you’re in tech, investing, building hardware, or watching mobility/AI sectors—this is a story to keep on your radar.

8. What to watch next

Announcement of a formal agreement between Tesla & Intel (terms, timeline, locations)

Details on the AI5 chip’s actual specs (performance vs Nvidia’s Blackwell, power, cost)

Progress on Tesla’s fab plans: location, funding, capacity

Impact on Intel’s foundry business: new customers, production ramp, yield

How existing suppliers (TSMC, Samsung) respond—will they innovate, cut costs, or lose volume

Stock market reactions and strategy shifts among auto/AI/hardware firms

Note: Content and images are for informational use only. For any concerns, contact us at info@rajasthaninews.com.

TSMC Optimistic Amid...

Related Post

Hot Categories

Recent News

Daily Newsletter

Get all the top stories from Blogs to keep track.